CAPY-Q.form

Sensitivity and robustness analysis of

FEM-based sheet metal forming processes

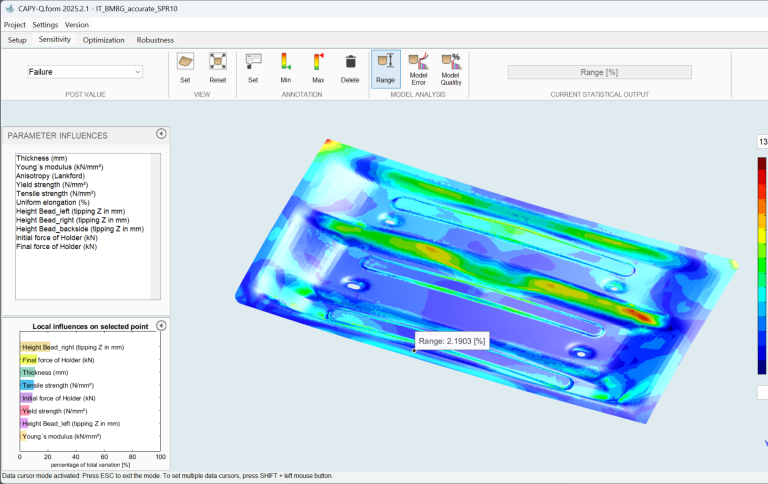

What is CAPY-Q.form

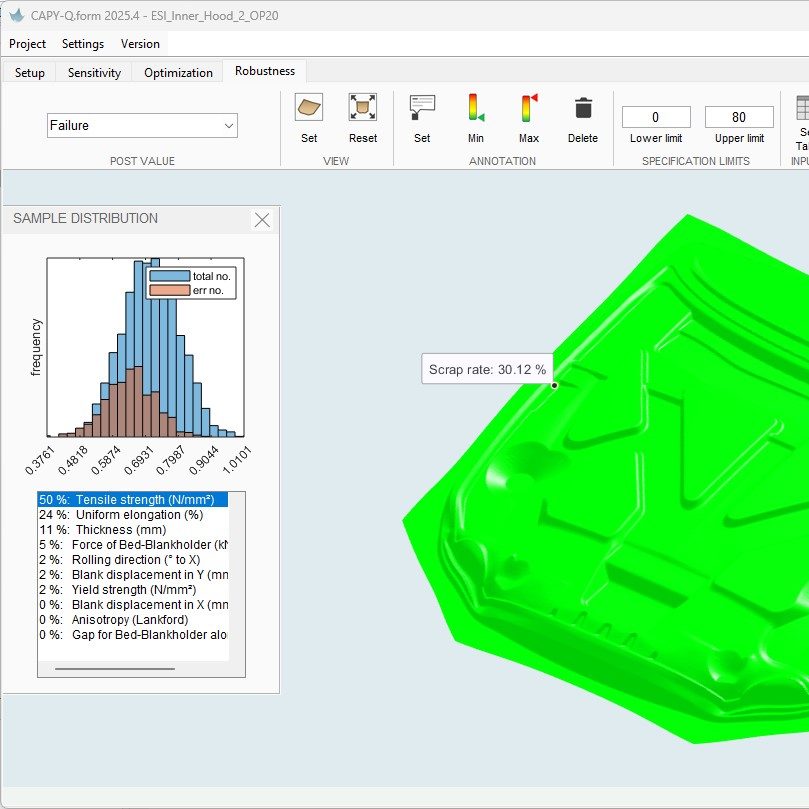

CAPY-Q.form is a statistical software for the efficient control and evaluation of FEM-based variant calculations during forming. The special feature of the software is the continuous 3D view of the statistical results on the FE mesh. This allows parameter sensitivities for relevant post variables (e.g. deviation, thinning) to be output at each FE mesh node of the drawn part. It is also possible to use sliders to optimize the quality of the drawn part based on the model or to identify an optimal process window for the drawing process using a robustness analysis.

Highlights of CAPY-Q.form

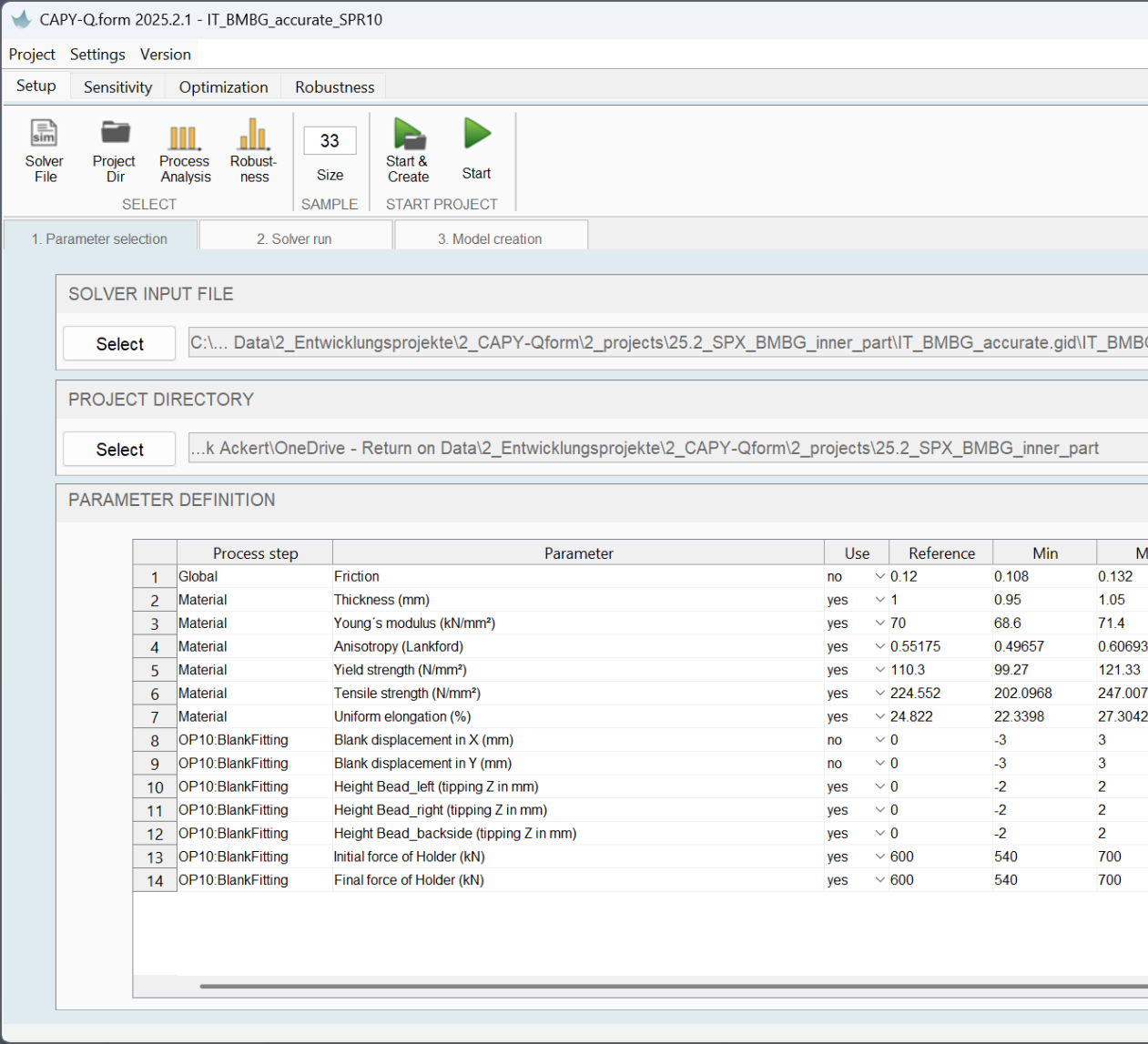

Design of experiments

Plan your simulation variants efficiently and conveniently with our DoE module.

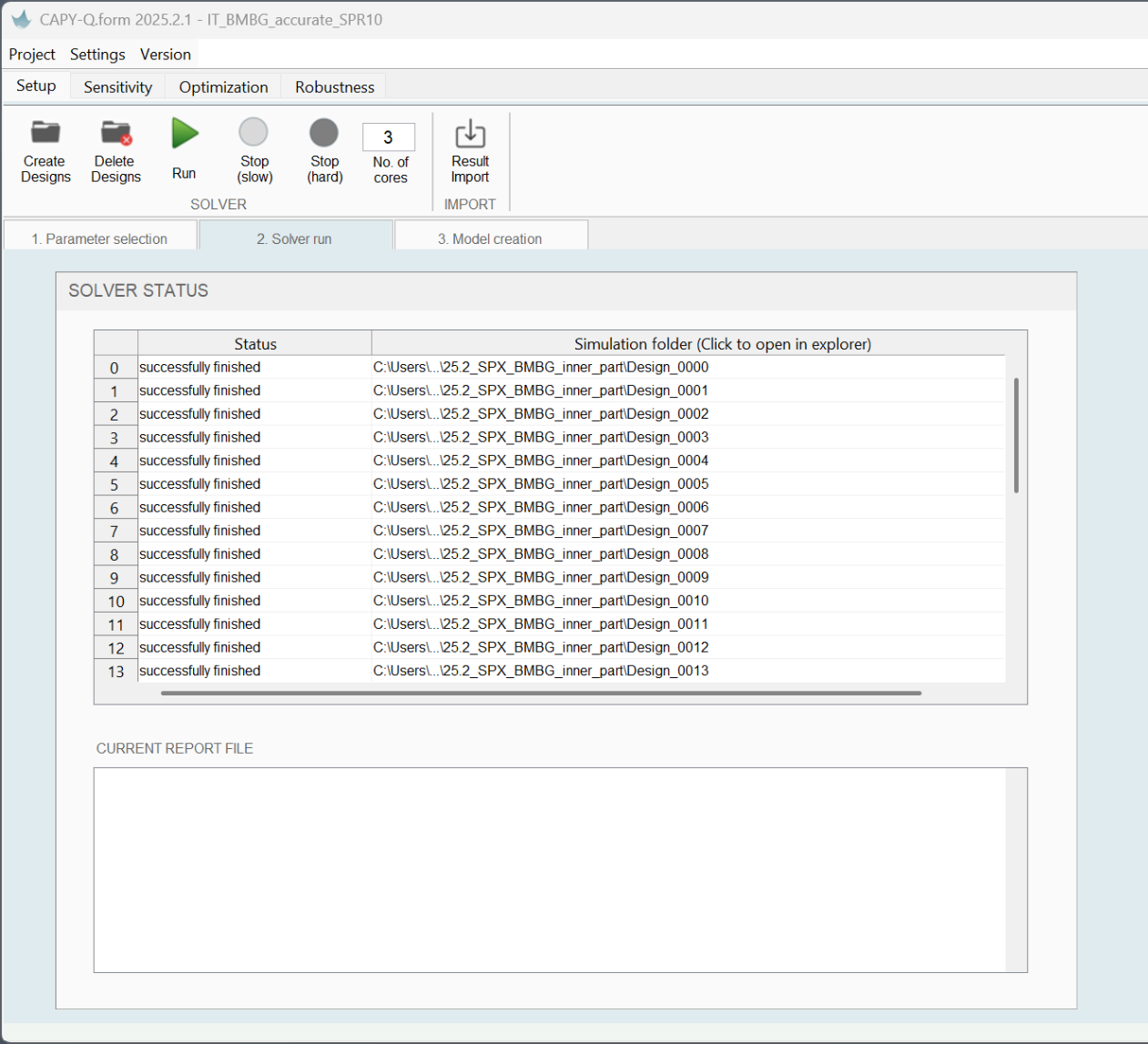

Solver control

All simulation variants are carried out automatically via an interface to the FE solver.

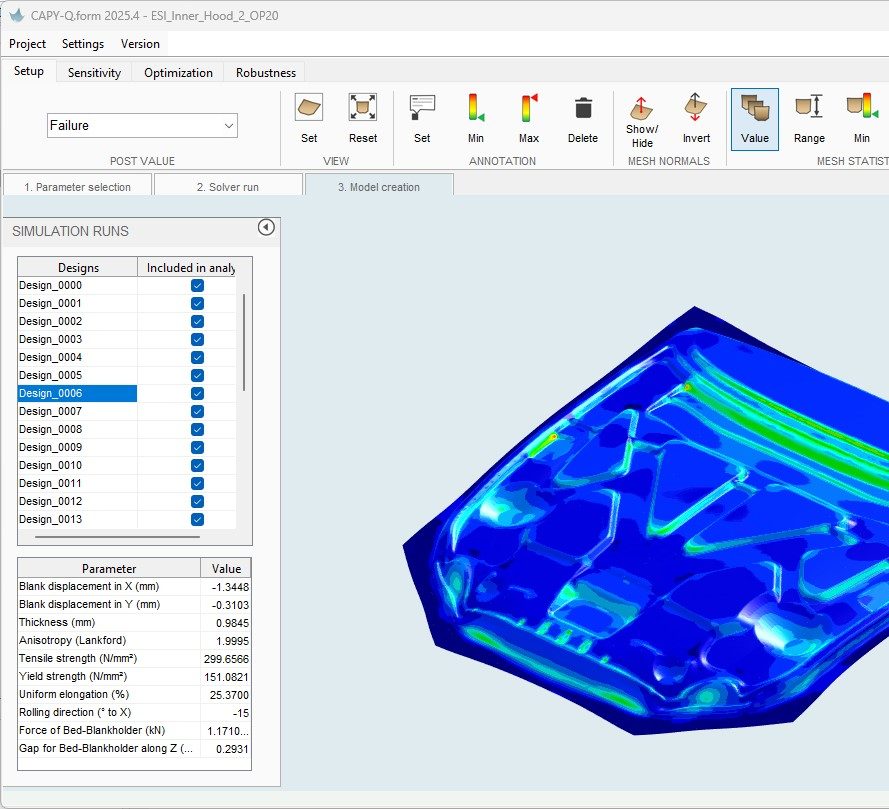

3D Mesh comparision

Compare the surface results of the variant simulation in our step-by-step evaluation.

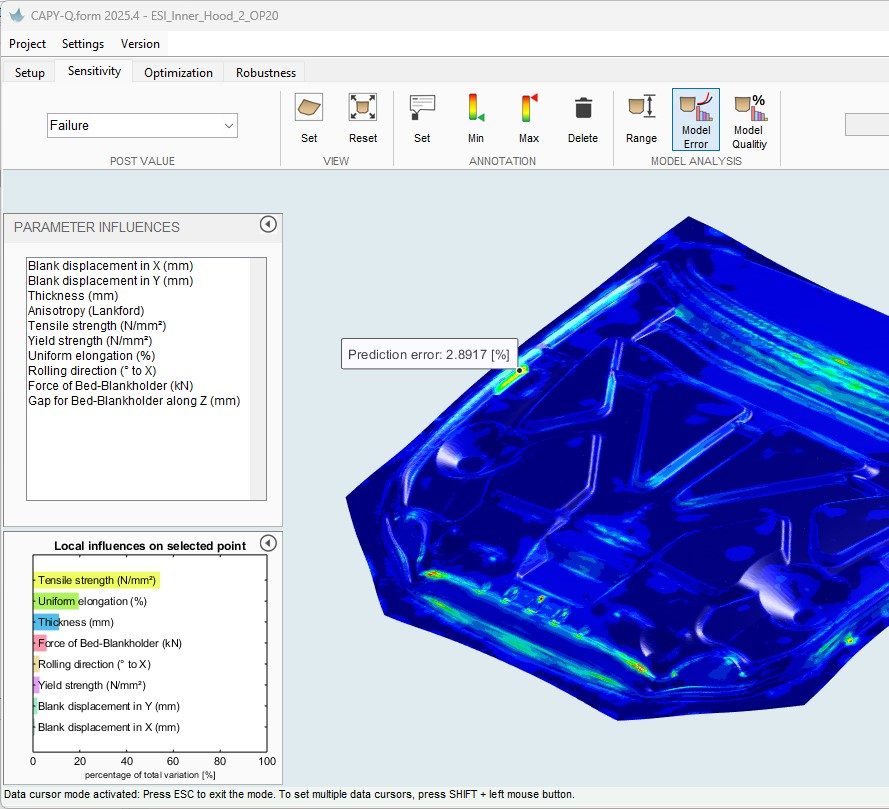

3D Sensitivitiy analysis

Determine the local influences of the input parameters for various FE post variables such as thinning or springback.

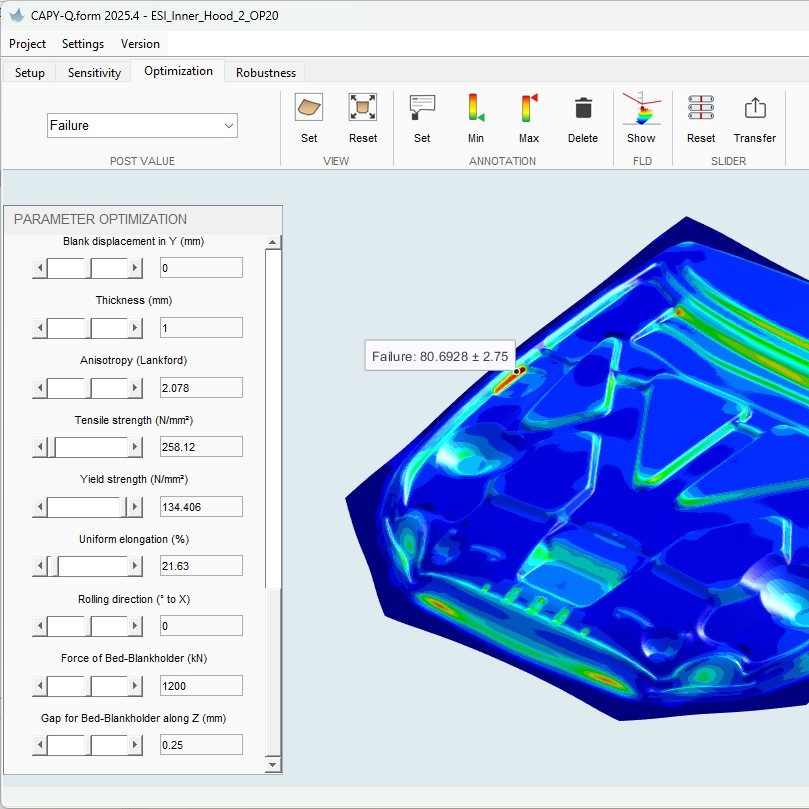

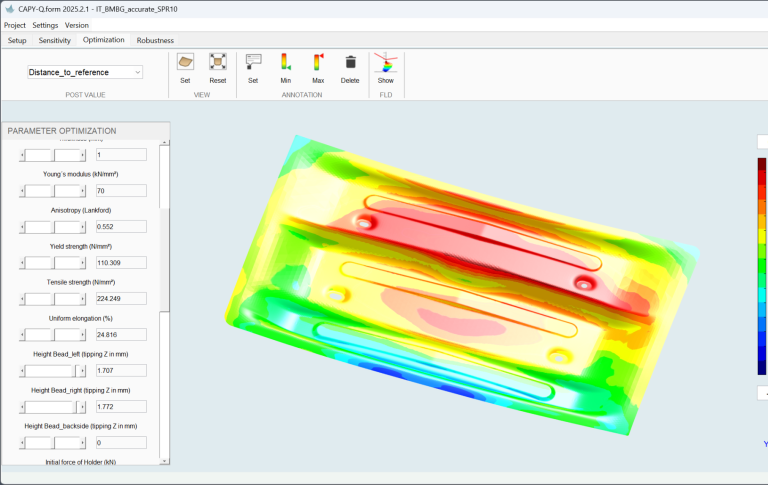

3D Model optimization

Optimize your drawn part by generating new model-based simulation results in real time without performing new time consuming FE simulations.

Benefits of CAPY-Q.form

- Simple definition of the input parameters to be varied

- Automated execution of the simulation variants via interface to the solver

- Generation of a sequential DoE plan to achieve maximum result quality with just a few simulations

- Automated model creation using linear and non-linear approaches

- 3D comparison of all simulation variants

- 3D sensitivity analysis to identify relevant inputs for various FE post variables (springback, thinning, failure)

- 3D robustness analysis to achieve a stable process window

- 3D optimization via slider

- Available for STAMPACK Xpress & ESI BM-STAMP